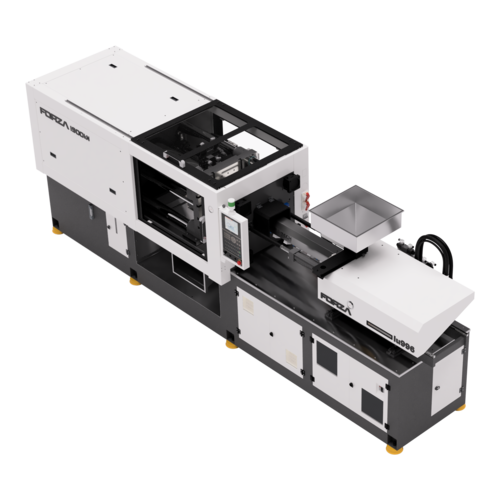

Injection Molding Machine

Product Details:

- Product Type Injection Molding Machine

- General Use For Industrial & Workshop Use

- Material Stainless Steel Alloy

- Automatic Yes

- Control System PLC Control

- Voltage 120-440 Volt (v)

- Color White & Black

- Click to View more

Injection Molding Machine Price

- 1000000 INR/Unit

- 1 Unit

Injection Molding Machine Specification

- Yes

- PLC Control

- Injection Molding Machine

- Stainless Steel Alloy

- White & Black

- For Industrial & Workshop Use

- 1 Year

- 120-440 Volt (v)

Injection Molding Machine Trade Information

- 1 Unit Per Day

- 1 Week

- All India

Product Description

PLC controlled Injection Molding Machine is reckoned for its long working life, standard clamping force and specific weight. The operator can change its material or color easily. This system allows its operator to select various injection combinations for better result. This Injection Molding Machine is compatible with different molds. Hydraulic unit of this equipment is energy efficient. Mold adjustment section of this equipment is controlled by hydraulic motor that uses gear coupling drive. Mold locking section of this system contains standard accessories like fixed plate and box shaped movable plate. Control unit of this machine can switch over different languages for the convenience of operator.

FAQs of Injection Molding Machine:

1. What is an Injection Molding Machine?

An injection molding machine is a particular assembling gadget used to create plastic parts and items through the injection molding process. It softens plastic materials and infuses them into a shape pit to make a great many plastic parts.

2. How Does an Injection Molding Machine Work?

An injection molding machine works by warming plastic pellets or granules until they become liquid. The liquid plastic is then infused into a form cavity under high tension. When the plastic cools and hardens, the shape is opened, and the completed part is launched out.

3. Where Are Injection Molding Machines Utilized?

Injection molding machines are utilized in different ventures to fabricate plastic items, parts, and parts. They are normally seen as in car, buyer products, hardware, clinical, bundling, and modern assembling.

4. What Are the Vital Parts of an Injection Molding Machine?

Key parts incorporate the container (for plastic material), the barrel, the screw, the shape, the cinching unit, the injection unit, and control frameworks.

5. What Kinds of Plastics Can Be Handled in Injection Molding Machines?

Injection molding machines can handle a large number of plastic materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), polystyrene (PS), and numerous others.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Injection Moulding Machine' category

|

FUTECH MACHINERY PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese