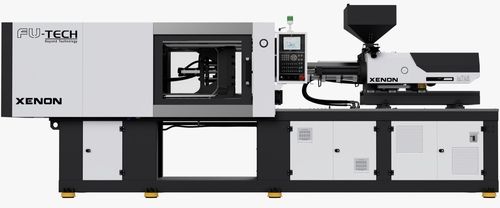

Pet Injection Moulding Machines With Ancillaries

1500000.00 - 6000000.00 INR/Unit

Product Details:

- Product Type Hydraulic Toggle Series

- Material Other

- Style Horizontal

- Capacity 50 Kg/hr

- Weight (kg) 5.5

- Computerized Yes

- Automatic Yes

- Click to View more

X

Pet Injection Moulding Machines With Ancillaries Price And Quantity

- 1 Number

- 1500000.00 - 6000000.00 INR/Unit

Pet Injection Moulding Machines With Ancillaries Product Specifications

- Yes

- 6*1.2*1.8

- 200

- Hydraulic Toggle Series

- 1800 Kilonewton (kN)

- Yes

- 5.5

- 50-55

- Horizontal

- Other

- 50 Kg/hr

- 400 Liter (L)

- 695

Pet Injection Moulding Machines With Ancillaries Trade Information

- 1 Number Per Day

- 1 Week

- All India

Product Description

Toggle type Injection moulding machine

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Injection Moulding Machine' category

|

FUTECH MACHINERY PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free