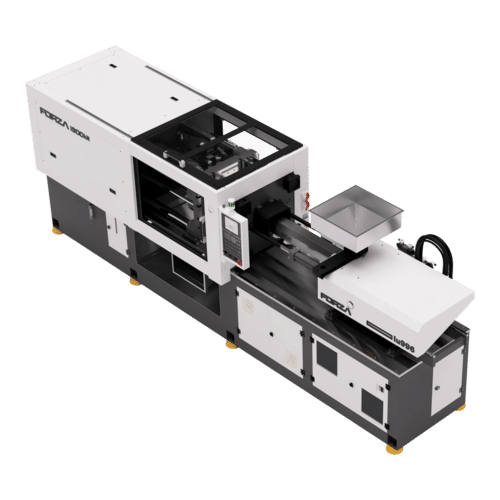

Vertical Plastic Injection Moulding Machine

Product Details:

- Product Type Vertical Plastic Injection Moulding Machine

- General Use Industrial

- Material Carbon Steel

- Computerized No

- Automatic No

- Feature ECO Friendly, Lower Energy Consumption

- Color Grey & White

- Click to View more

Vertical Plastic Injection Moulding Machine Price

- 1000000 INR/Unit

- 1 Unit

Vertical Plastic Injection Moulding Machine Specification

- ECO Friendly, Lower Energy Consumption

- No

- Carbon Steel

- Grey & White

- Industrial

- Vertical Plastic Injection Moulding Machine

- 1 Year

- No

Vertical Plastic Injection Moulding Machine Trade Information

- 1 Unit Per Day

- 1 Week

Product Description

Some advantages of vertical injection moulding machines include:

- Smaller machine footprint, which can be useful in limited space environments.

- Improved moulding precision and accuracy due to gravity-assisted moulding.

- Ability to mould complex parts with multiple cavities or inserts.

- Reduced risk of air entrapment, which can improve part quality.

FAQs of Vertical Plastic Injection Moulding Machine:

1. What is a Vertical Plastic Injection Trim Machine?

A vertical plastic injection shaping machine is a sort of injection forming machine where the form and the injection unit are vertically situated, instead of the more normal level setup.

2. How Does a Vertical Plastic Injection Trim Machine Work?

In a vertical injection forming machine, the shape is found vertically over the injection unit. Liquid plastic is infused into the form depression from the base or side of the shape. The shape is then clasped vertically, and the plastic part is framed as the form closes.

3. Where Are Vertical Plastic Injection Trim Machines Utilized?

Vertical plastic injection shaping machines are utilized for various applications, particularly when space is restricted. They are usually utilized for embed shaping, overmolding, and creating leaves behind complex calculations.

4. What Kinds of Parts Can Vertical Plastic Injection Embellishment Machines Produce?

Vertical machines can deliver a great many parts, including electronic parts, clinical gadgets, car parts, connectors, and then some.

5. Will Vertical Plastic Injection Embellishment Machines Handle Various Materials?

Indeed, vertical machines can deal with different thermoplastic materials usually utilized in injection forming.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Injection Moulding Machine' category

|

FUTECH MACHINERY PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free